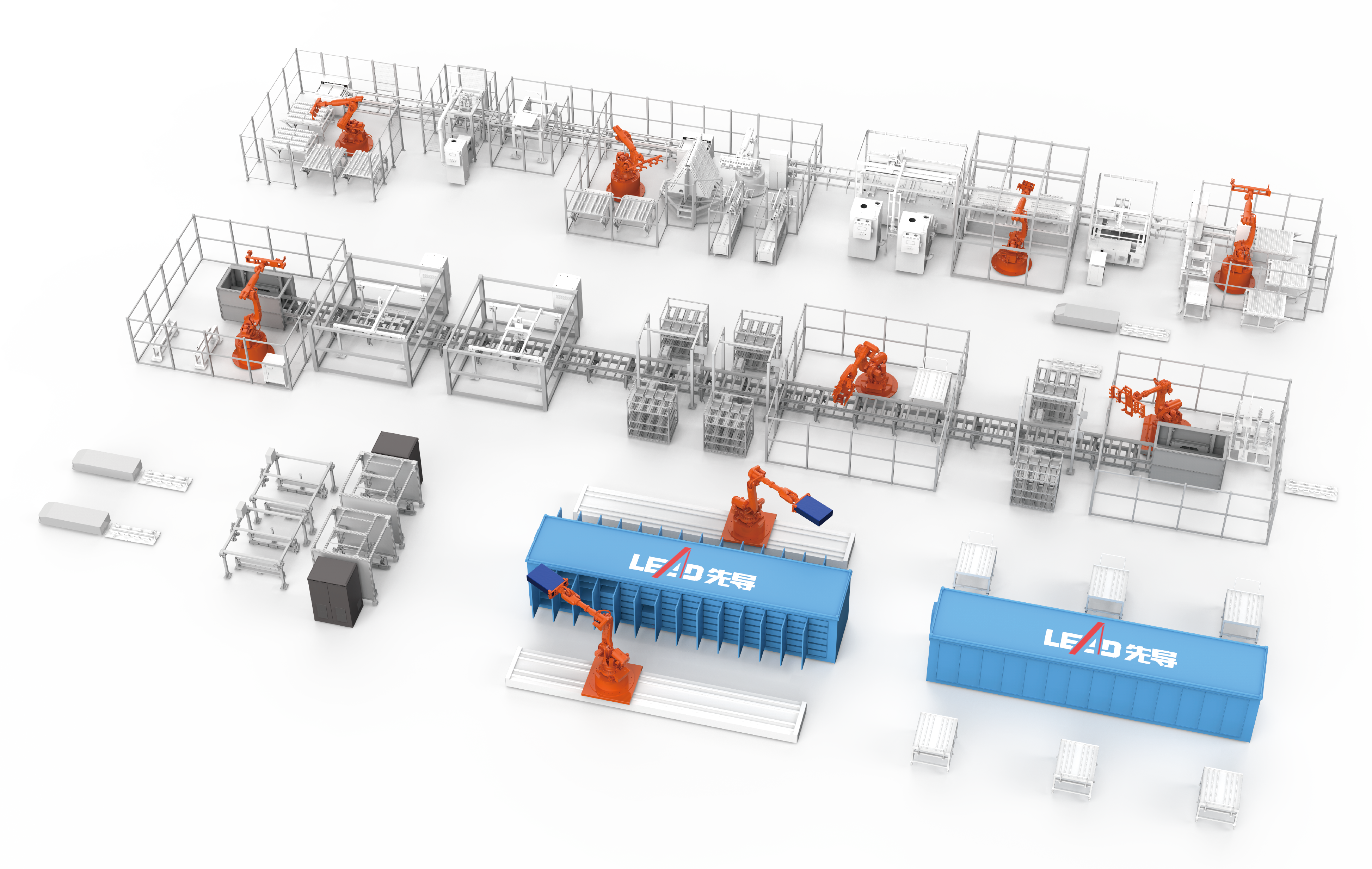

As the world’s leading lithium-ion battery intelligent manufacturing turnkey solution provider, LEAD offers comprehensive solutions for battery Module/Pack/CTP/Energy Storage Container intelligent production lines, and e-motor off-line testing. With years of expertise in intelligent equipment, we’ve partnered with TOP OEMs and battery manufacturers, solidifying our position as a key player in battery production solutions.

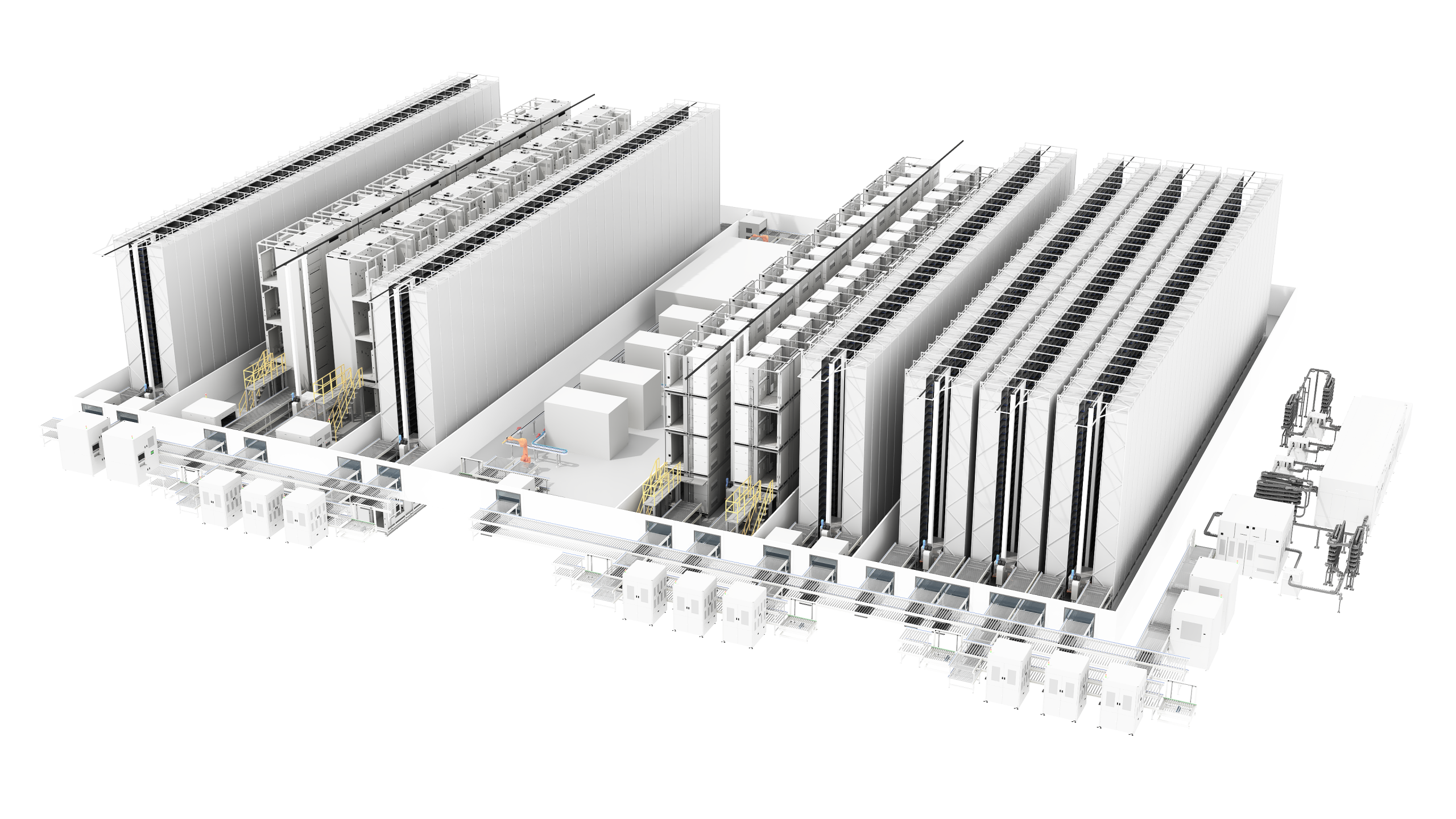

Leveraging self-developed core technology, we deliver end-to-end production line solutions for diverse battery Packs and e-drive off-line testing. Our services span factory modeling, simulation, special machine development, MES design, and intelligent warehousing, enabling rapid deployment and efficient production at customer sites. We are also the only provider worldwide that owns 100% independent intellectual property rights for the whole lithium-ion battery production line.

The overall Module/Pack/CTP/energy storage container production line we provide covers core processes such as cell stacking, group laser welding, coating/foaming, clustering, screwing, testing, etc.; the e-drive off-line testing is based on self-developed core software system to realize the core processes such as the automatic cooling cycle of the bench, test clamping and integrating the functional equipment, etc. Combined with the intelligent logistics system and MES system independently developed by LEAD, we further improve the level of production line intelligence and commit to building an intelligent factory for lithium-ion battery enterprises.

As the manufacturing process of battery Module/Pack/CTP/energy storage container and e-drive off-line test line continues to develop in the direction of full automation, high degree of integration and informatization, our pack battery storage production line will continue to improve the in-depth development capabilities, constantly adapt to the production needs of highly modular products, and provide our customers with full life-cycle solutions for the entire line.